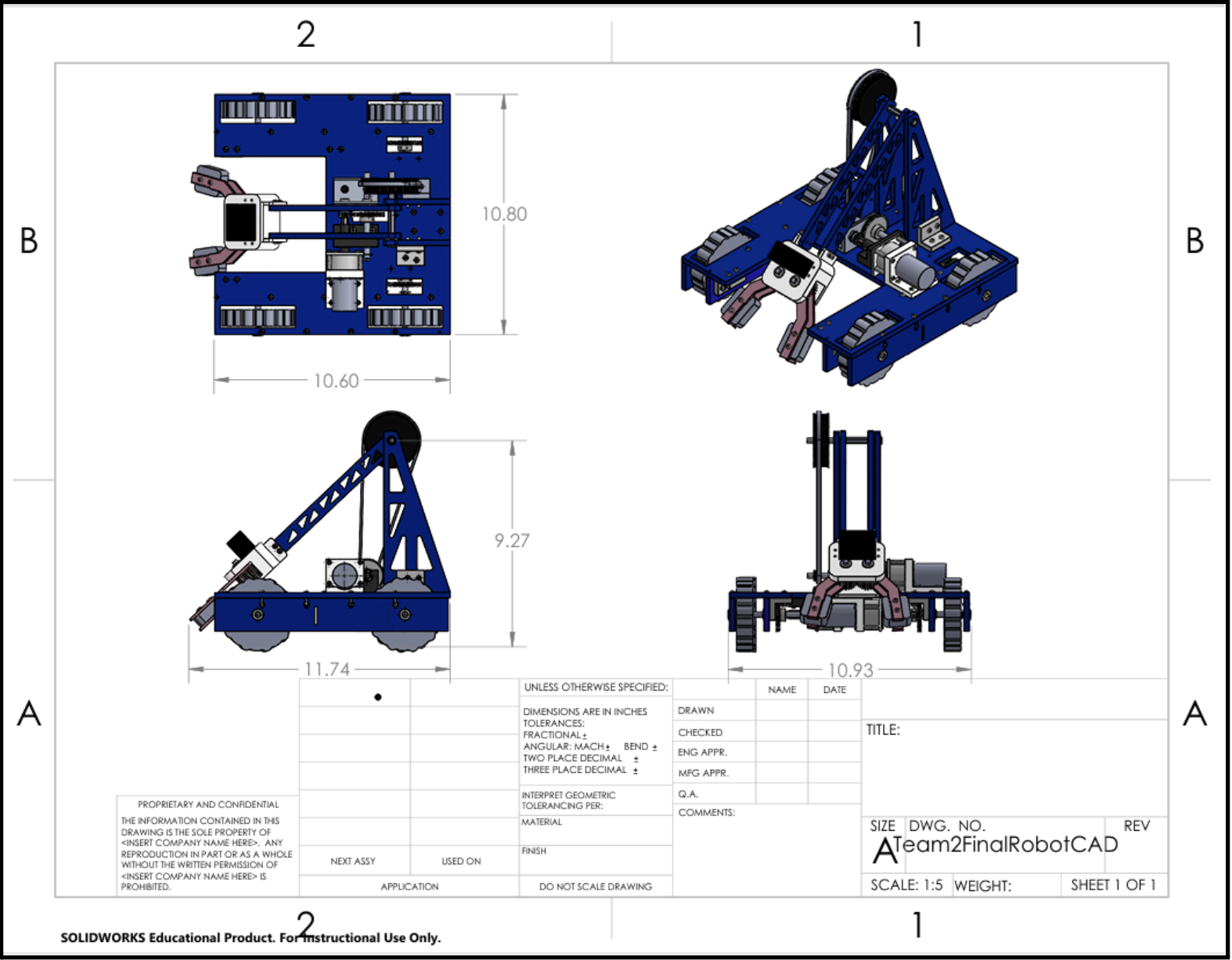

Robot CAD Design & Engineering Drawings

ES-51 Turf Wars Competition Robot

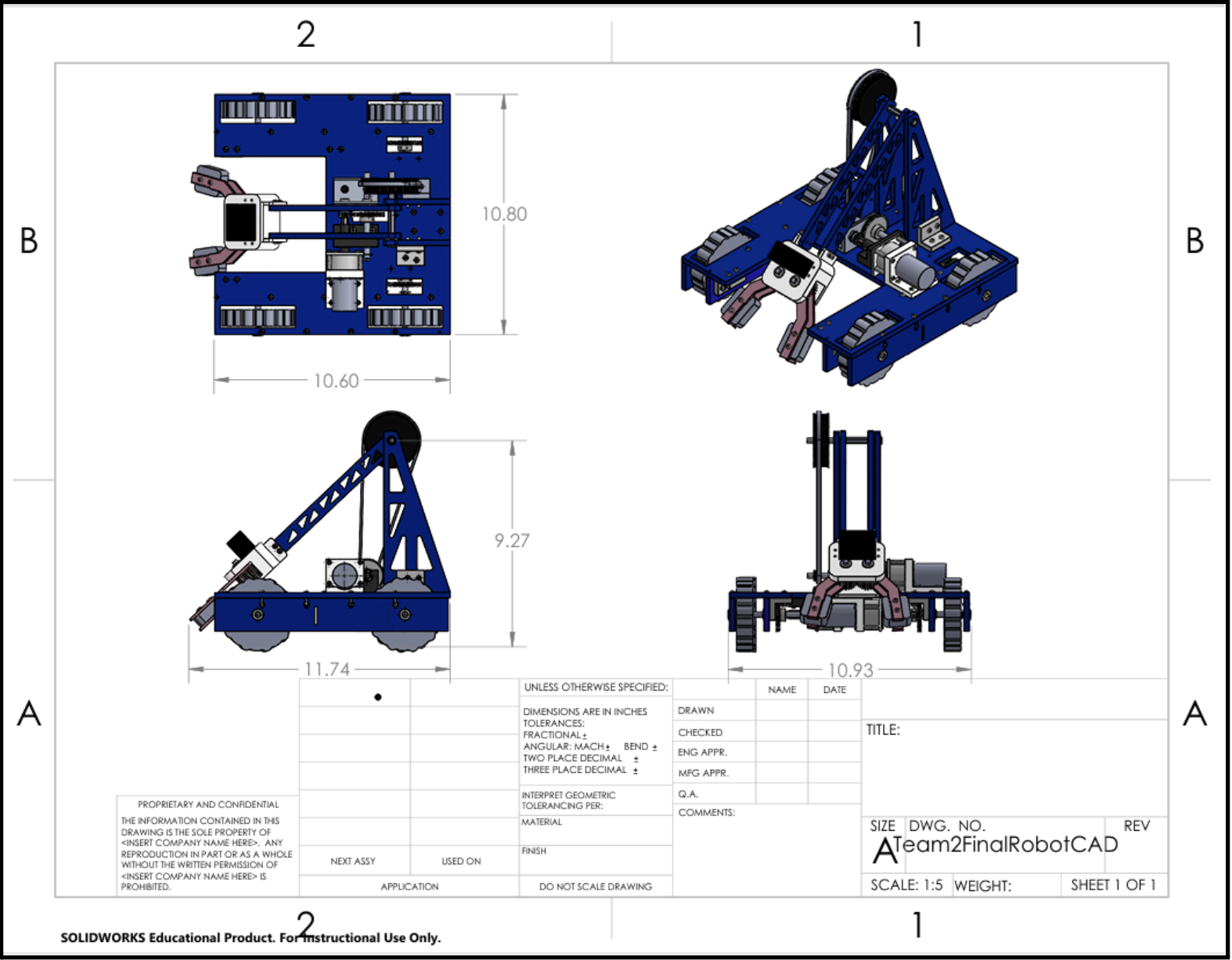

A compact 4-wheel-drive robot designed for Harvard's ES-51 Computer Aided Machine Design course. Built to climb 30-degree ramps and place objects into goals at heights up to 21 inches, featuring precision-machined components and cast Ecoflex silicone wheels.

Machined Robot in action during the ES-51 Turf Wars competition

Comprehensive engineering report documenting the concept development, analysis, manufacturing, and testing of Machined Robot. Includes drivetrain torque calculations, arm loading analysis, tipping stability studies, and competition performance results.

Rear-wheel-drive with two motor-gearbox assemblies, 3:1 gear reduction using 16T pinion and 48T wheel gear. Provides 39N theoretical tractive force.

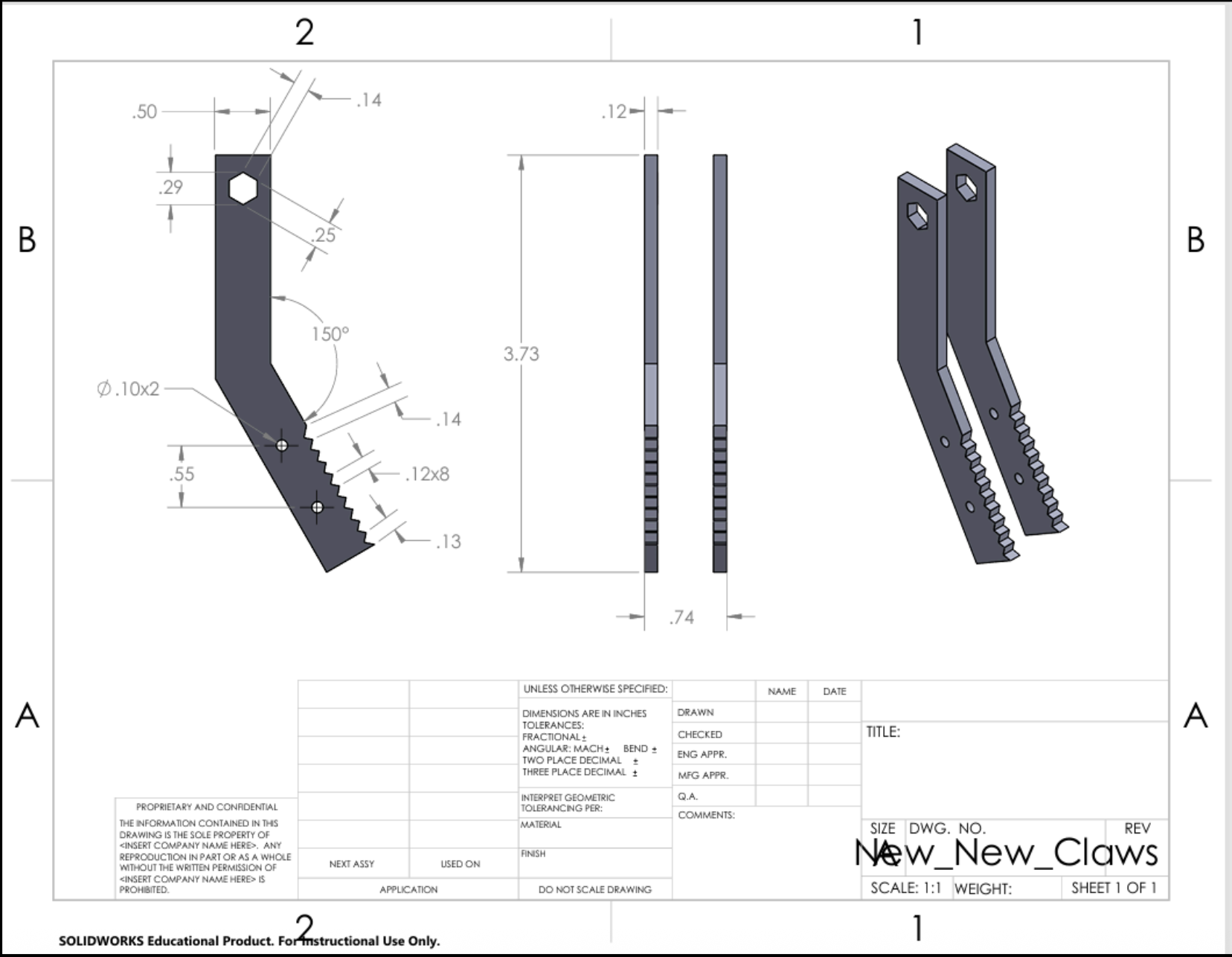

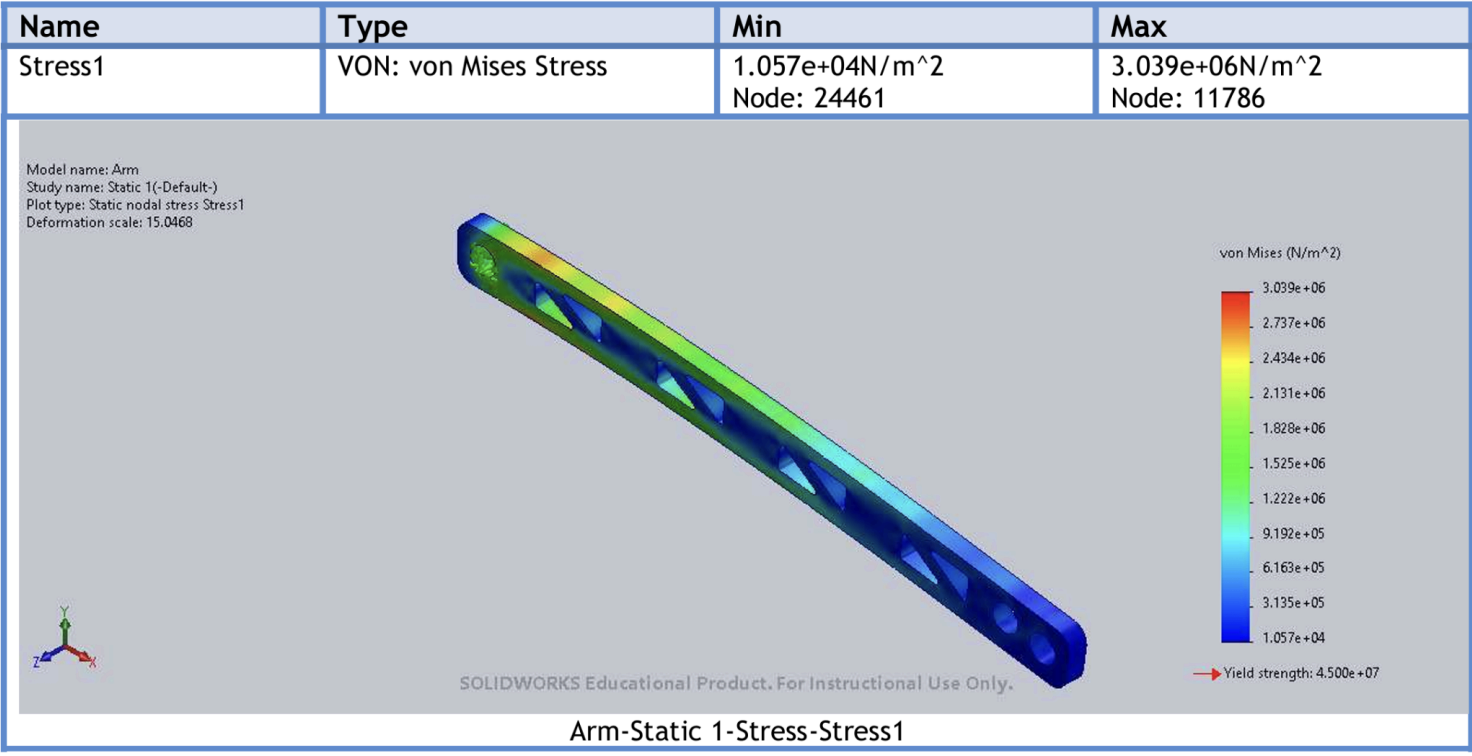

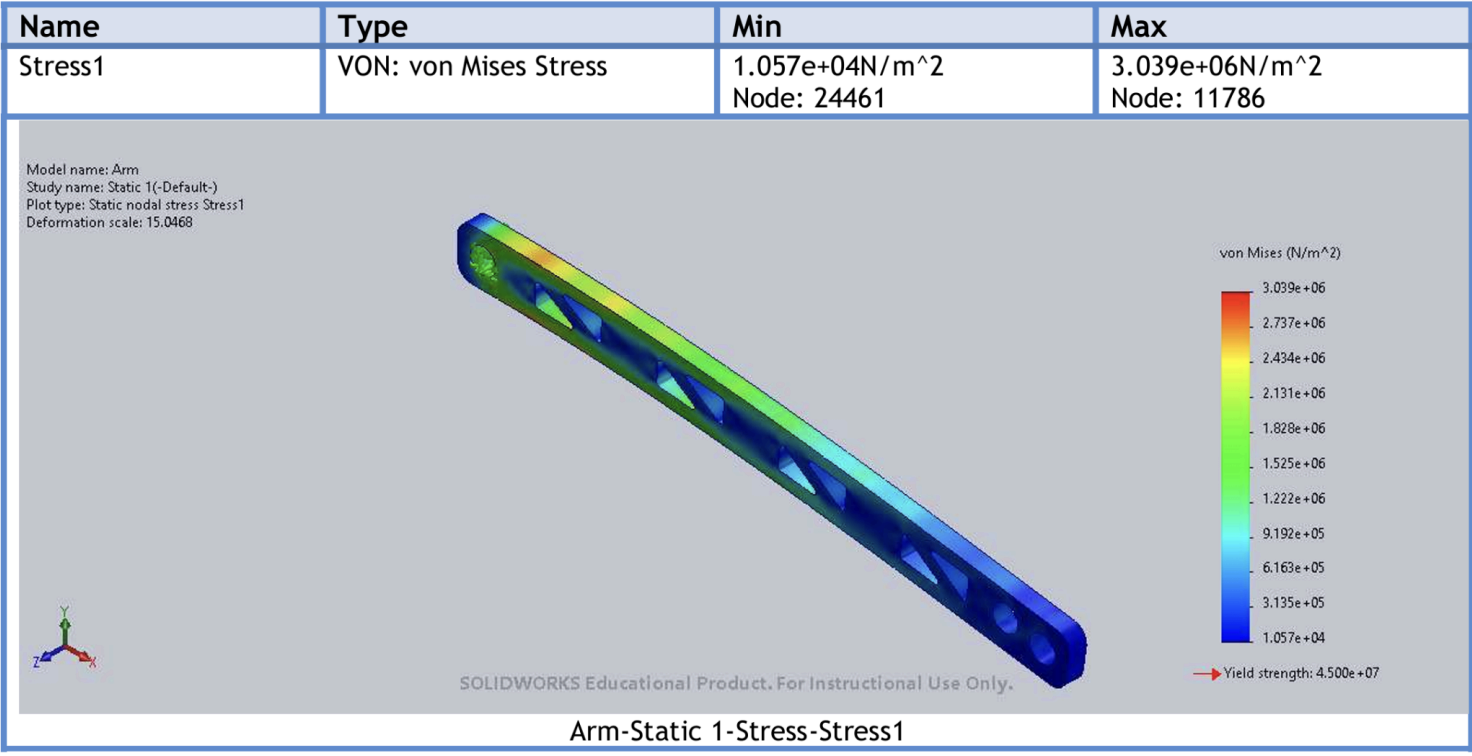

Single motor drives arm through 6:1 reduction, providing torque to lift 0.27 lb objects at full extension. Reaches 7", 14", and 21" goal heights.

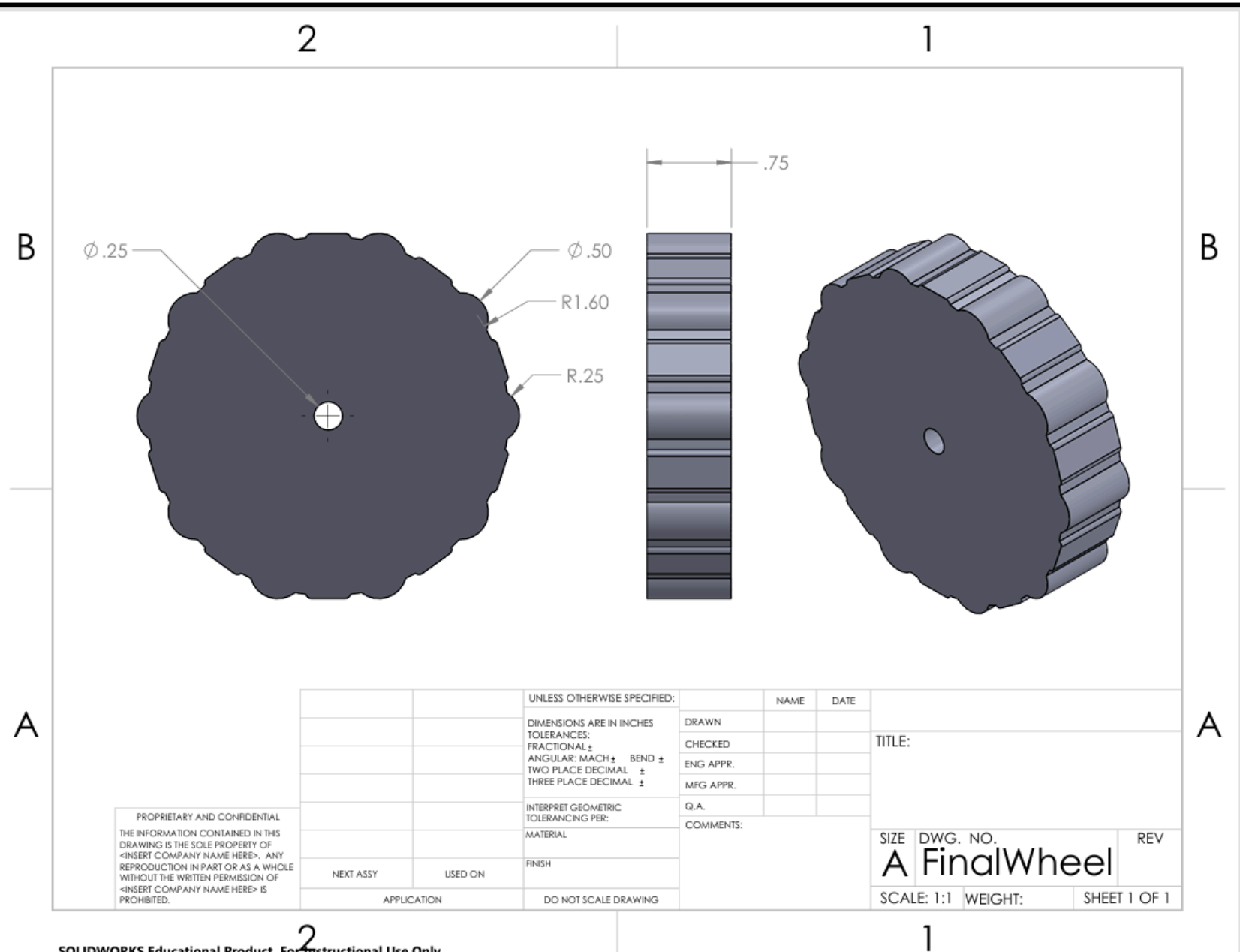

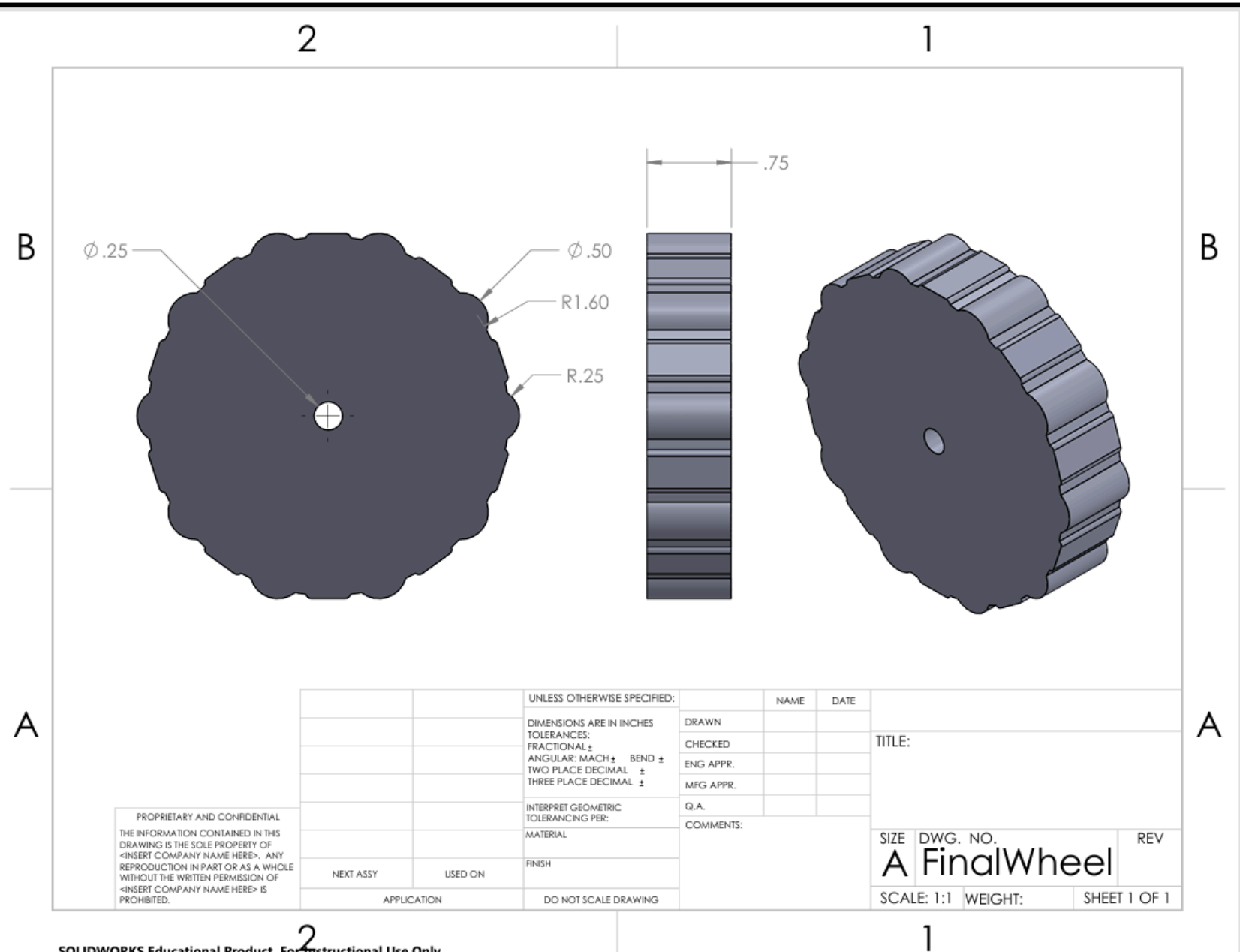

Cast silicone wheels (1.625" radius, 0.75" width) with ~0.8 coefficient of friction, enabling reliable 30-degree ramp climbing with 1.6x safety factor.

Fits within 11" x 11" x 11" "Box of Justice" starting constraint, then expands for competition. Final dimensions: 10.60" x 11.74" x 10.80".

Navigate both 15-degree and 30-degree incline ramps without slipping or tipping over during 4-minute matches.

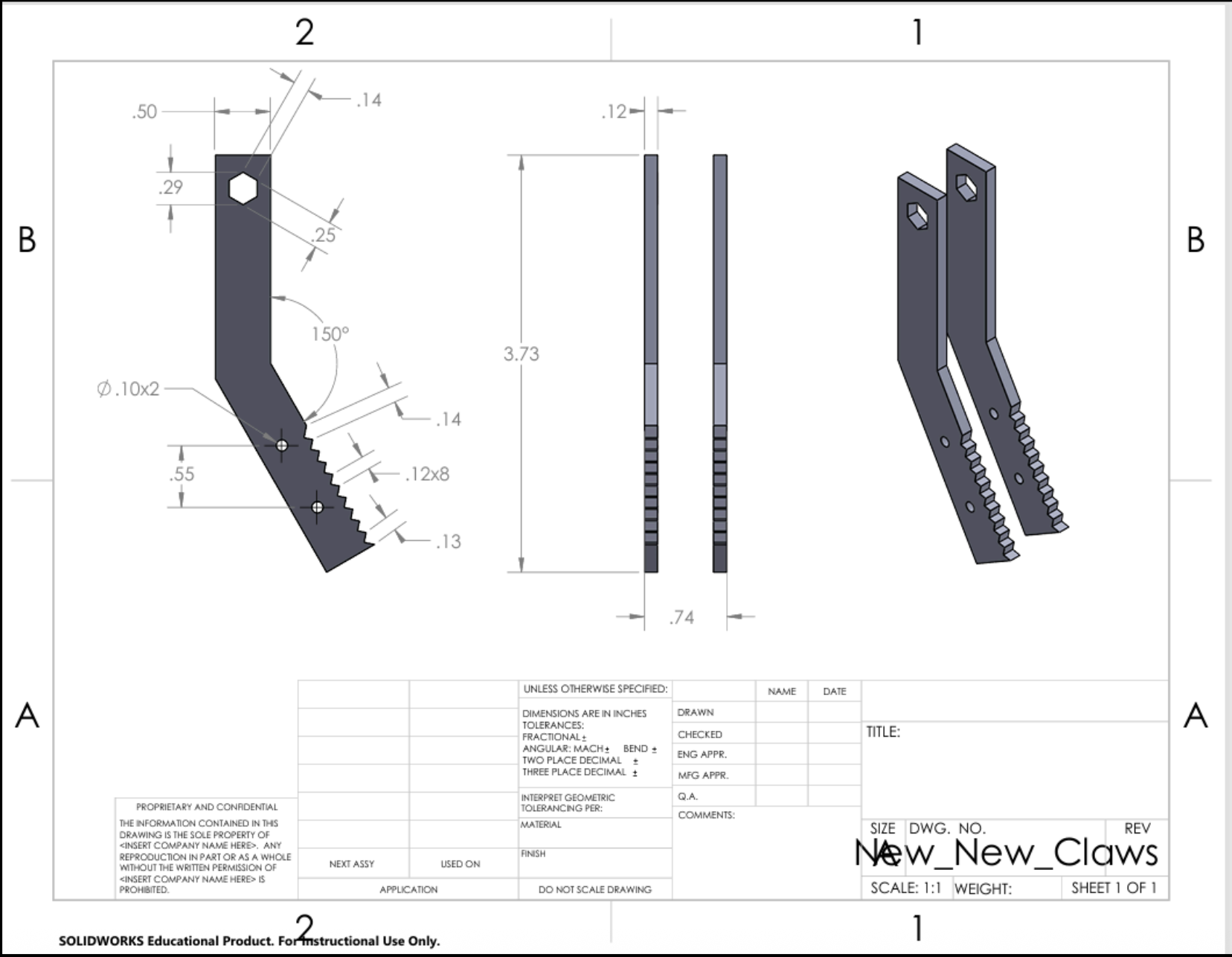

Control and place irregular objects including tennis balls, dog toys, and wooden blocks into elevated scoring goals.

Score in goals at three different heights: 7 inches, 14 inches, and 21 inches above the playing field.

Limited to three drill motors total (two drivetrain, one arm) operating within 1.2-1.6V safe voltage range.

At 1.6V, each motor provides 0.269 Nm continuous torque. With 3:1 gearing, wheel torque reaches 0.807 Nm per wheel, generating 19.5N tractive force each.

30-degree ramp requires 10.9N climbing force. Friction-limited traction provides 15N (safety factor 1.38), ensuring reliable ascent.

6:1 gear reduction on arm motor provides sufficient torque to lift irregular objects weighing up to 0.27 lbs at maximum arm extension.

Center of mass analysis ensures robot remains stable on 30-degree inclines with and without objects, preventing backward tipping.

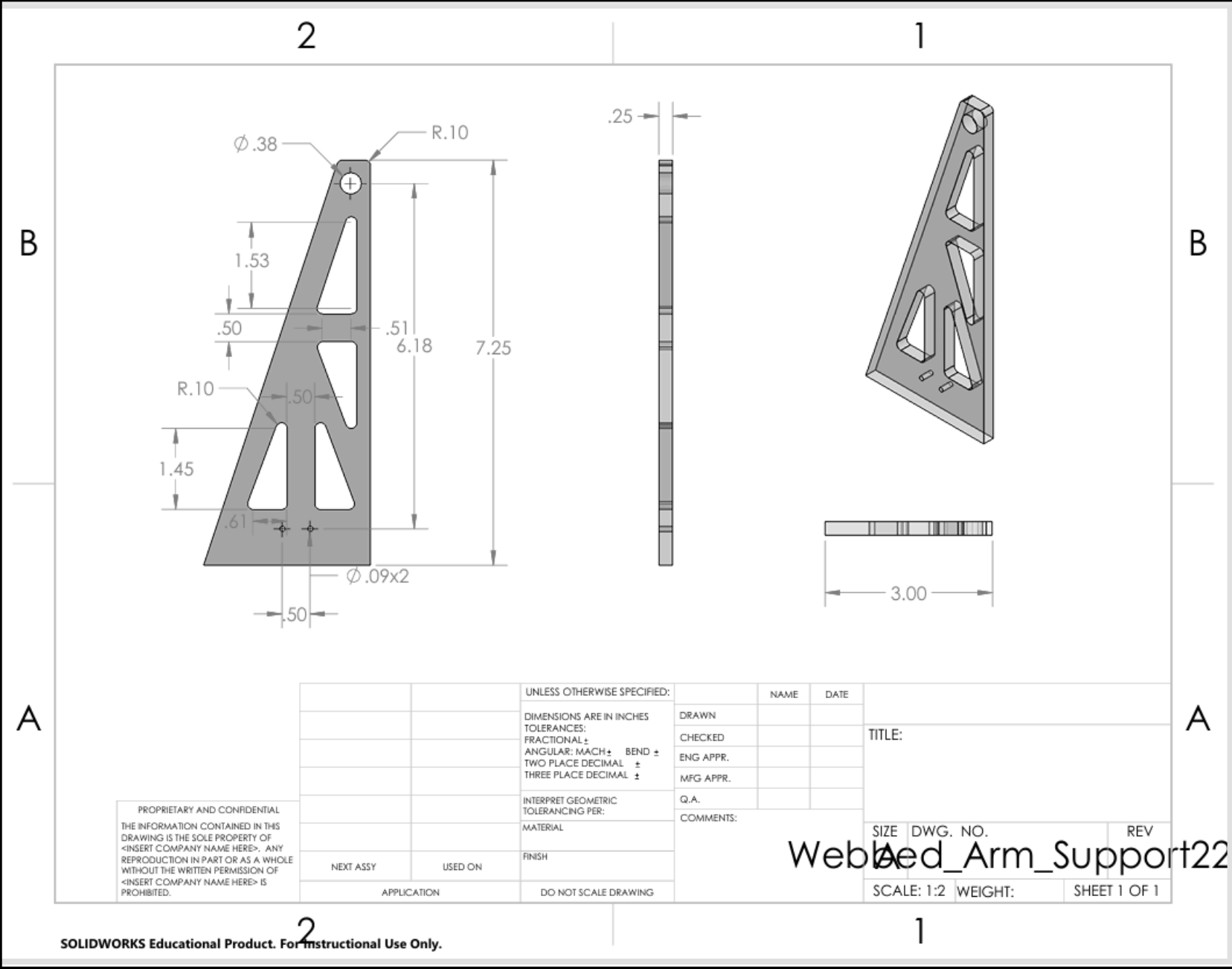

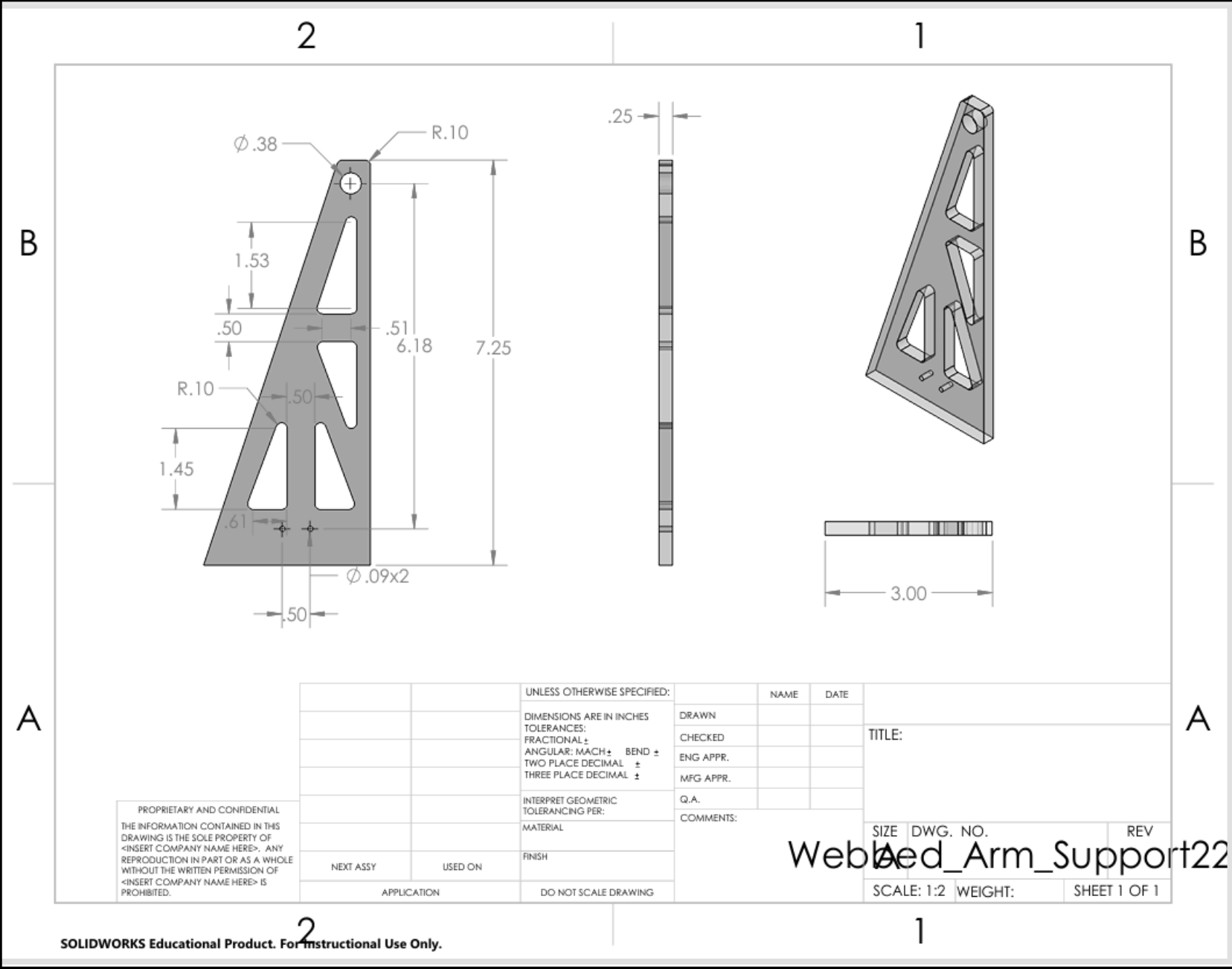

Precision-cut acrylic and plywood components for the chassis frame and structural supports.

Custom brackets, motor mounts, and claw mechanism components produced with additive manufacturing.

Precision aluminum components for critical load-bearing parts and gear mounting surfaces.

Cast Ecoflex 50 silicone wheels in custom molds for optimal traction on competition turf surface.