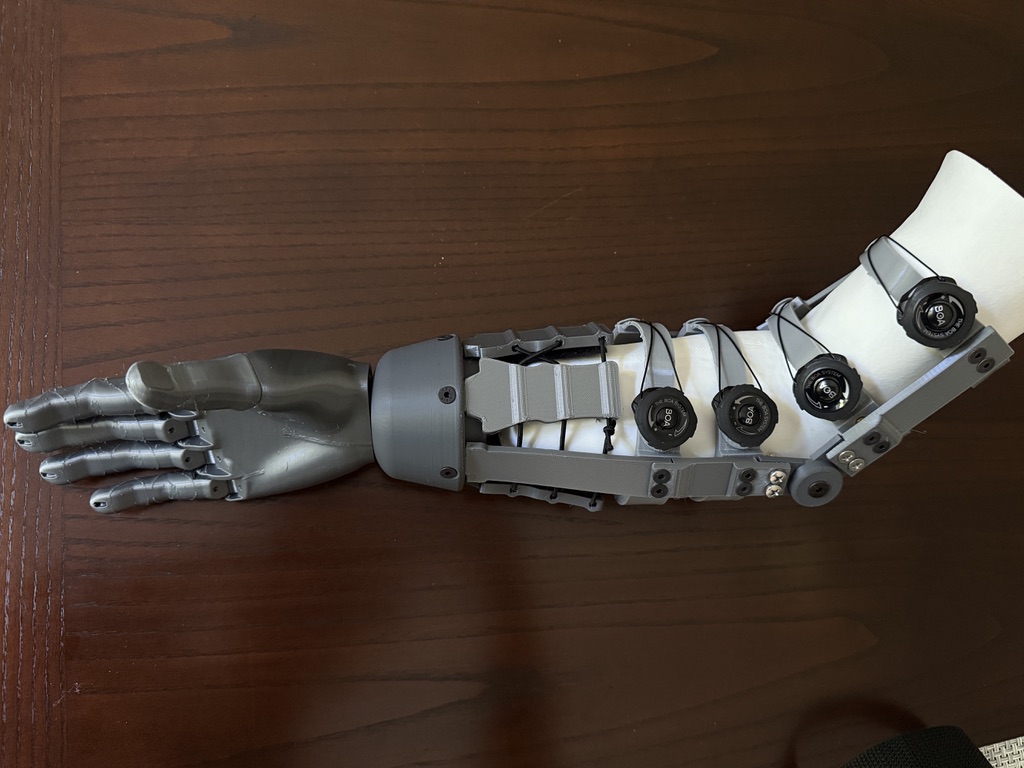

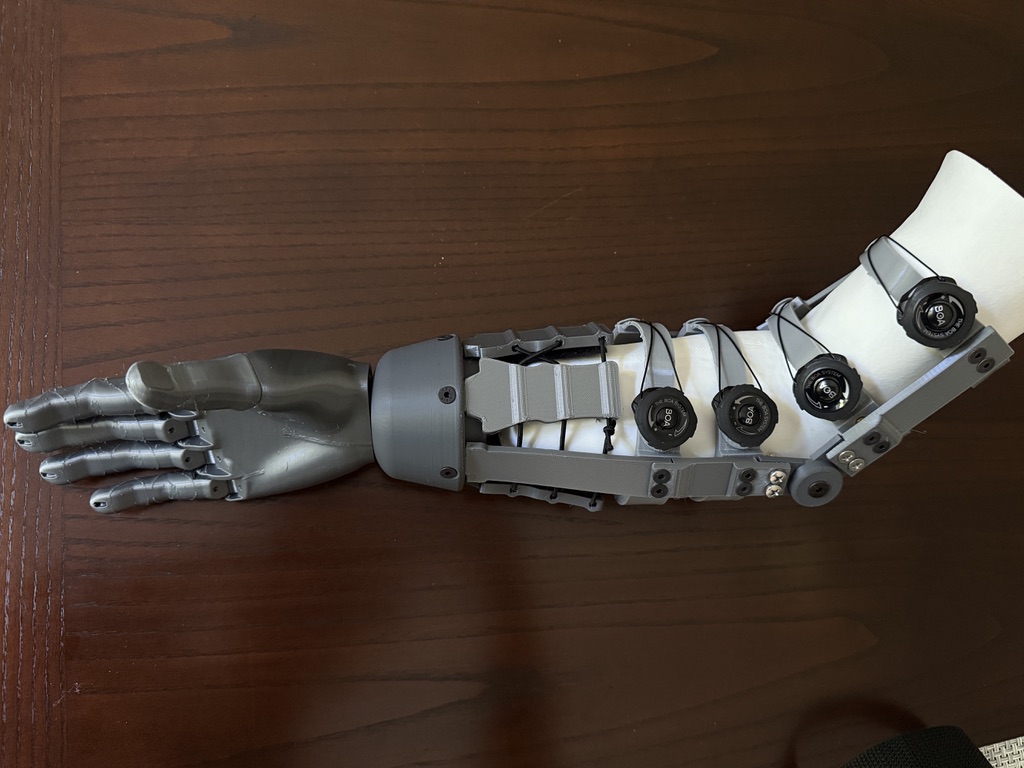

Product Gallery

Revolutionary Prosthetic Startup

Universal-fit prosthetic arm reducing cost by 99% ($40 vs $10,000+) while eliminating the need for trained prosthetists. Patented design serves 40 million amputees in developing countries through innovative adjustable socket technology.

40 million amputees in developing countries lack access to prosthetics due to (1) cost barriers ($10,000+ vs limited resources) and (2) requirement for trained prosthetists for custom fitting. Current solutions are unaffordable, low quality, and uncomfortable.

Patented universal-fit socket featuring strategically placed real-time adjustable clasps with skin-safe silicone padding. Enables mass production and <5-minute fitting by minimally trained personnel, eliminating prosthetist dependency. Manufacturing via FDM 3D printing using carbon fiber-infused filament (rigid) and TPU (flexible) with variable infill densities.

Tested with multiple amputees, passing ISO load-bearing standards with comfort ratings exceeding traditional custom-fit prosthetics. Cost: $40 (99% reduction). Deployment partnerships: Jaipur Foot (India), Operation Renew (Ukraine), Direct Relief. Leading 8-member MIT/Harvard team.

Comprehensive engineering demonstration of the patented universal-fit socket technology and assembly process.

Official United States Patent for the universal-fit prosthetic technology that forms the foundation of Mobilis. This patent protects the innovative design and manufacturing process that makes accessible prosthetics possible.

"Tinkering for Change: Universal-Fit 3D Printed Prosthetic at 2024 Regeneron Competition"

Read Article"Virginia High School Students Compete in National Science & Math Competition"

Read Article